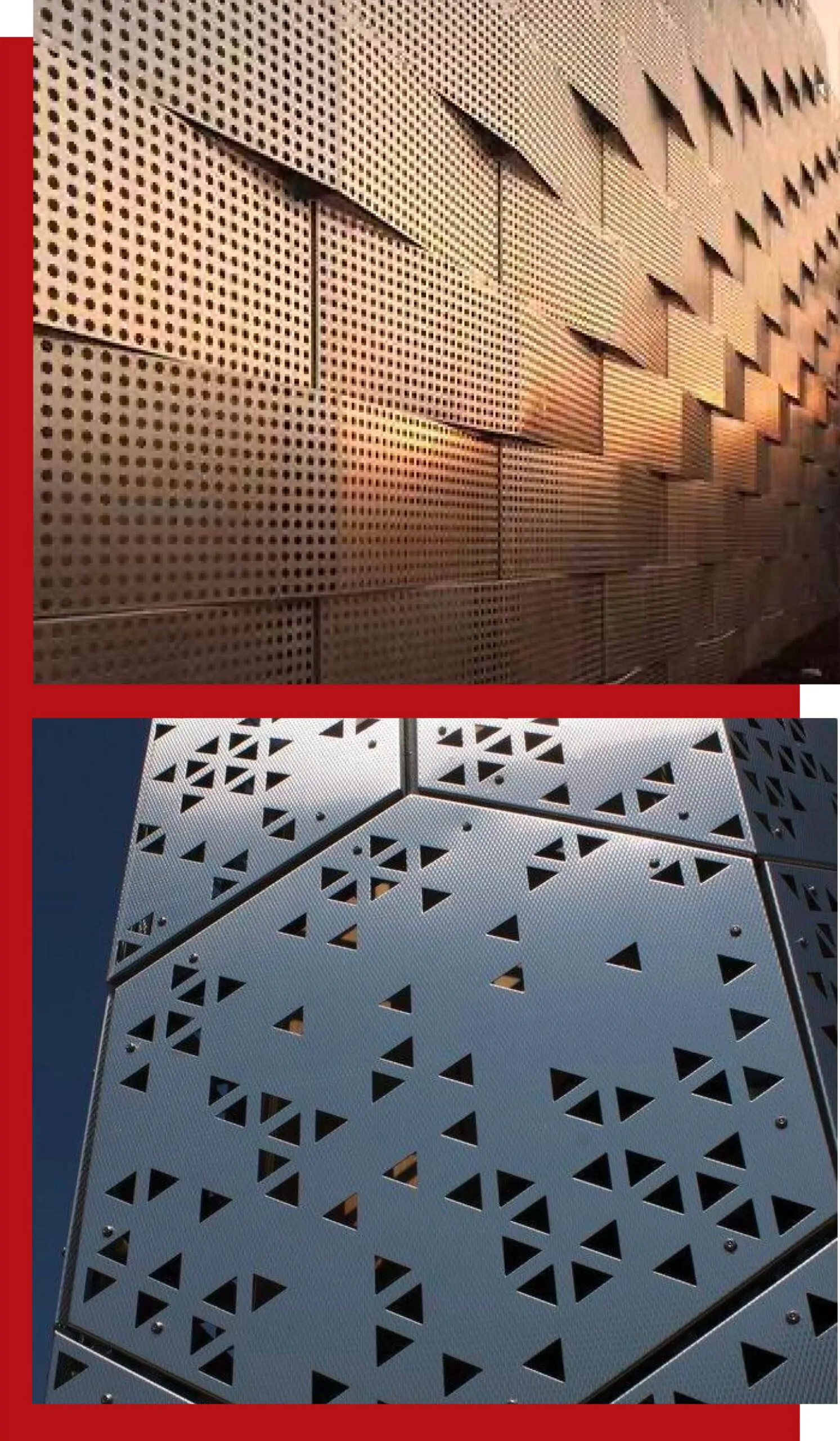

JZM’s façade and structural steel systems are crafted for performance, visual excellence, and reliability — setting new benchmarks in modern construction.

Whether used in commercial towers, transport terminals, or public institutions, our stainless steel perforated panels offer a unique blend of visual appeal, airflow efficiency, and structural reliability.

Typical tolerances include:

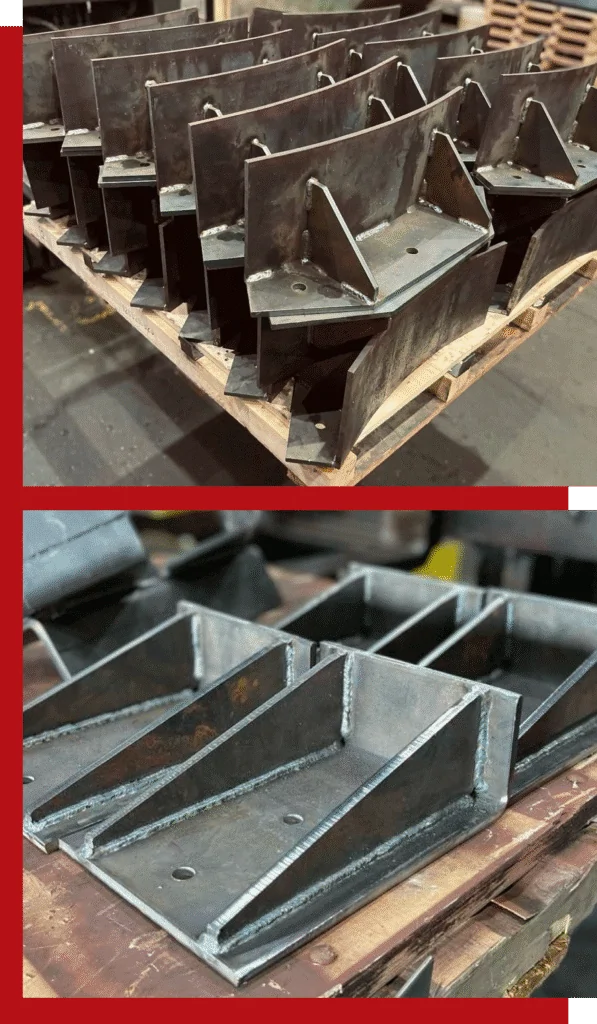

Welding operations are performed in accordance with

BS EN ISO 15614-1,

BS EN ISO 9606-1, and

AWS D1.1/D1.6, using certified welders and qualified WPS/PQR procedures.

All load-bearing or critical welds undergo non-destructive testing (NDT),

such as ultrasonic testing (UT) or magnetic particle inspection (MPI),

in compliance with BS EN ISO 5817 Class B or C, depending on structural demands.

Our bracket assemblies are suitable for:

Surface finishes are available in

HDG (Hot Dip Galvanized to BS EN ISO 1461),

fluorocarbon coatings,

electropolished stainless steel, or

bead-blasted matte finish depending on project specifications.

These façade brackets are delivered with complete

MTCs (Material Test Certificates),

welding inspection reports, and installation documentation.

Project 4

Our custom accessories are engineered to interface seamlessly with unitized and stick curtain walls, canopies, louver supports, and structural fixings, enabling secure and long-lasting performance under dynamic and static loading

With our vertically integrated facility, we offer:

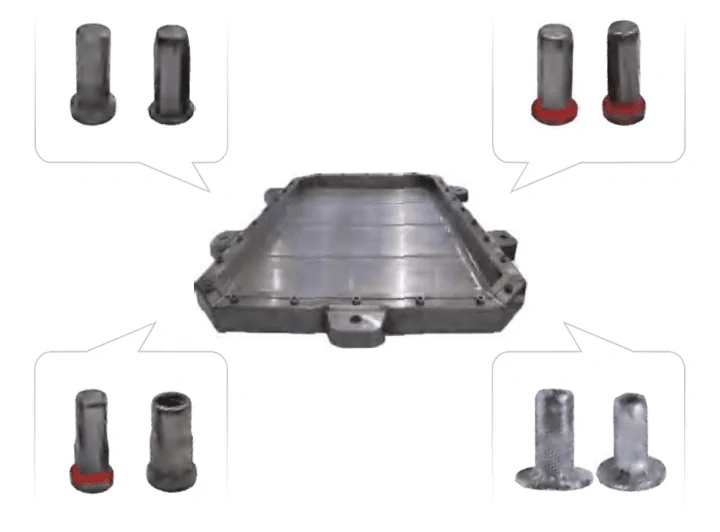

At JZM Metals, our rivet and fastening solutions combine precision engineering with global compliance standards to meet the most demanding architectural and industrial applications. Designed for structural reliability and aesthetic precision, our rivets are ideal for façade systems, curtain walls, and complex steel assemblies.

Manufactured using high-grade stainless steel, aluminum, and carbon steel, each rivet is engineered for consistent grip, tensile strength, and corrosion resistance. Our automated forming and inspection systems ensure dimensional accuracy and flawless surface finish across every batch.

Available in multiple configurations — dome head, countersunk, and large flange — our rivets meet international standards such as GB, DIN, and ISO, supporting both custom and large-scale production needs. Whether for load-bearing structures or precision façade joints, JZM rivets deliver performance you can trust.

We are proud to be at the forefront of intelligent steel fabrication and facade engineering in China, delivering reliable and sophisticated solutions for both domestic and international markets.

© 2025 JZM • Designed by SlideExpo