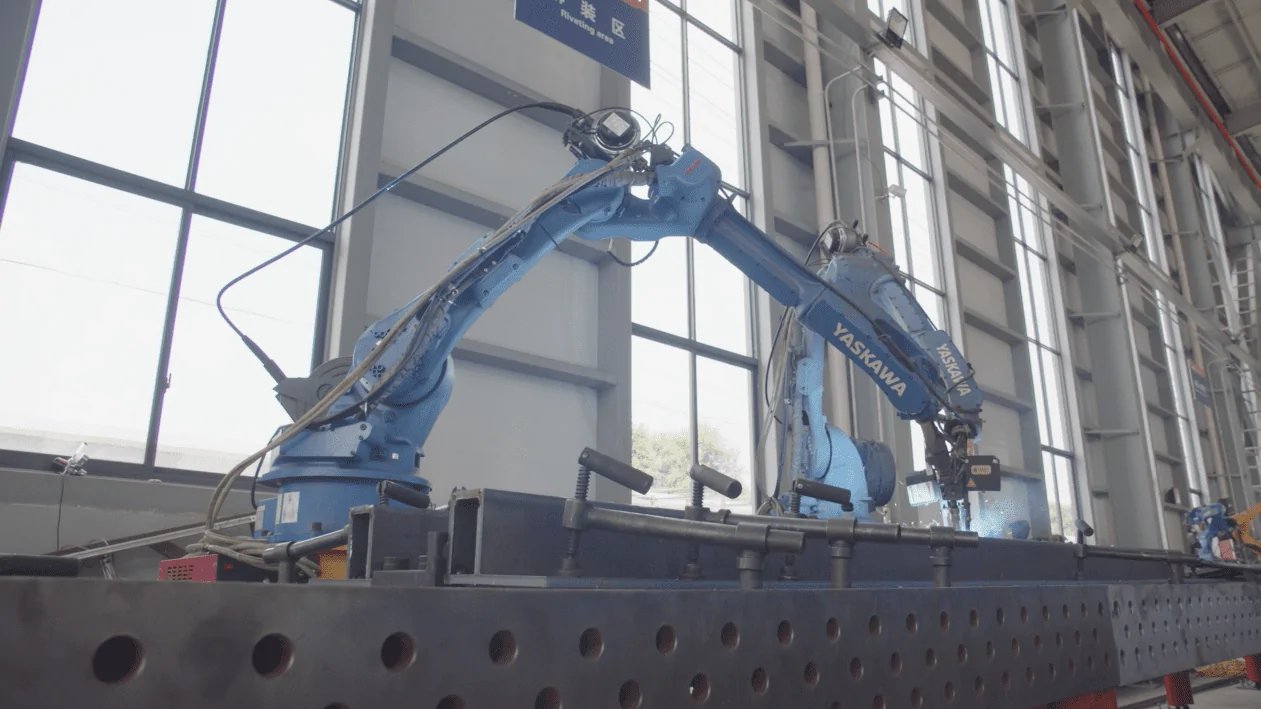

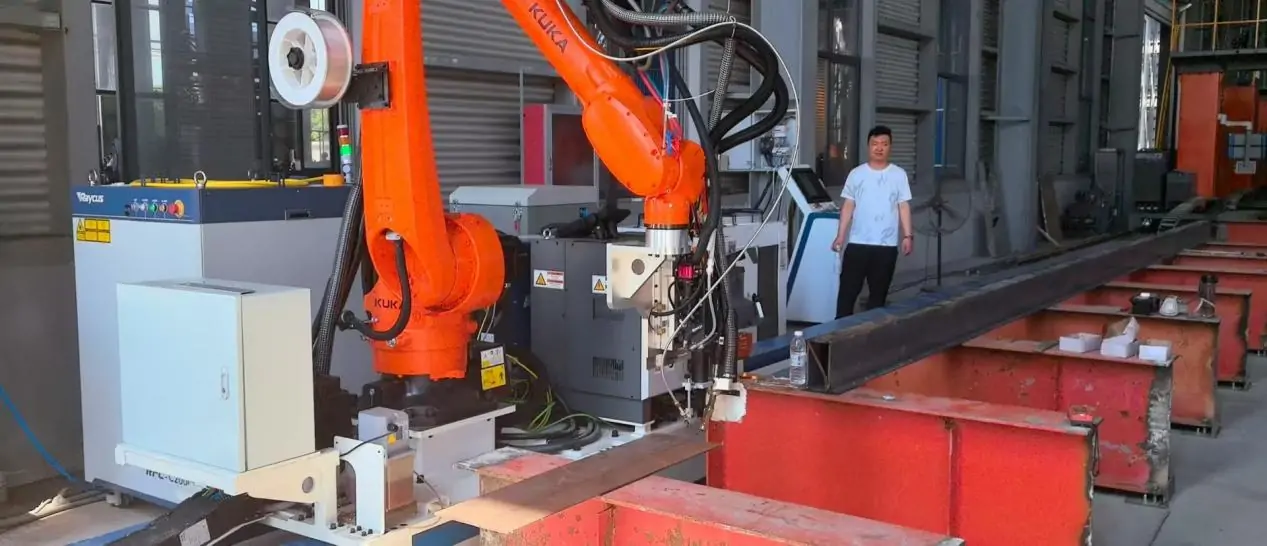

Our advanced robotic welding facility features a fleet of 11 , 7-axis robots from leading manufacturers including Yaskawa, ABB, and KUKA, enabling flexible, high-precision welding across a wide range of metal fabrication applications. Each robotic arm is equipped with interchangeable welding sources—including laser, plasma, ARC (TIG/MIG), and hybrid welding systems that combine laser and ARC processes—ensuring optimal results based on material type, joint configuration, and structural demands. These intelligent robotic systems are programmed through offline simulation and CNC-integrated welding paths, delivering superior repeatability, penetration accuracy, and spatter-free seams. Withß synchronized multi-axis motion, our robots maintain consistent torch angles and heat control even on complex geometries, effectively eliminating human variability. This cutting-edge setup not only enhances welding quality and cycle time, but also supports batch manufacturing, 24/7 operation, and stringent compliance with EN ISO 15614, 9606, and AWS D1.1 standards—establishing JinZhimu as a leader in automated structural and architectural welding.

For high-quality steel products, the requirements for cutting precision, edge smoothness and material adaptability are much higher than those for ordinary steel processing. The 30000W laser cutting machine precisely meets these core demands. In terms of cutting precision, the equipment is equipped with a dual-drive servo system and a dynamic focusing laser head, combined with a micrometer-level positioning sensor, which can control the cutting tolerance within ±0.05mm. Even for the complex patterns and small diameters (the smallest can be φ1mm circular holes) commonly found in high-quality steel products, it can achieve error-free shaping and perfectly present the design details.

In terms of processing efficiency and material handling capacity, the ultra-high power of 30,000W enables it to easily surpass the cutting limits of traditional equipment: for high-strength and delicate steel with a thickness of up to 30mm (such as wear-resistant alloy steel plates), the cutting speed is increased by 80% compared to the 12,000W equipment. The cutting cycle for a single 1.5m×3m sheet is shortened to less than 10 minutes, significantly meeting the timeliness requirements for batch production of delicate steel products. At the same time, its unique beam mode can reduce the heat affected zone (HAZ) to below 0.1mm, avoiding deformation and performance degradation of delicate steel due to high temperature, ensuring that the mechanical properties and surface texture of the material are not damaged after cutting, especially suitable for high-end delicate steel components with strict requirements for flatness and toughness (such as precision mechanical enclosures, decorative metal curtain wall components).

The bevel laser cutting machine is a high-precision equipment specifically designed for processing bevels of pipes and plates. With its 0-45° full-angle cutting capability and laser precise processing technology, it has become a key equipment in fields such as pipeline welding and steel structure connection. It can not only meet the diverse requirements for bevel processing, but also completely solve the efficiency and accuracy problems of traditional bevel processing.

Regarding the adaptability of processing for different materials, the equipment performs equally well. Whether it is stainless steel, carbon steel or high-strength alloy materials, the laser energy can be intelligently adjusted according to the material characteristics, ensuring that the thermal influence zone is reduced (controlled within 0.2mm) during the cutting of the bevel, avoiding material deformation or performance degradation due to high temperature. It is particularly suitable for high-end equipment manufacturing scenarios that require high precision. In addition, the equipment integrates an automatic loading and unloading system and a waste collection system, eliminating the need for manual intervention throughout the process. This not only reduces labor costs but also reduces safety hazards during the bevel processing (such as metal debris flying) by 40%.

For the common pain points of the client, such as “the cumbersome switching of multiple specifications of bevels” and “high costs for small batch customization”, the equipment achieves one-click switching of different angles and materials by presetting 100 + bevel process parameters. The changeover time is shortened to within 2 minutes, and the cost of small batch customization processing is reduced by 40%. At the same time, its integrated design eliminates the multi-device circulation process of “cutting + beveling” in traditional processing, increasing material utilization by 15% and further saving raw material costs for the client.

The bevel laser cutting machine has “full-angle precise cutting, efficient integrated processing, and multi-material compatibility” as its core competitiveness. It not only provides a one-stop solution for bevel processing, but also helps the client improve welding quality, shorten production cycles, and reduce overall costs. In the competition in fields such as pipeline engineering and heavy machinery, it has formed a significant advantage.

The bevel laser cutting machine is a high-precision equipment specifically designed for processing bevels of pipes and plates. With its 0-45° full-angle cutting capability and laser precise processing technology, it has become a key equipment in fields such as pipeline welding and steel structure connection. It can not only meet the diverse requirements for bevel processing, but also completely solve the efficiency and accuracy problems of traditional bevel processing.

The 16-meter rail welding robot, with its extremely long working range and precise welding technology, has become the core equipment for welding large structural components. It demonstrates unique advantages in handling long-sized materials and directly contributes to enhancing the market competitiveness of the final products.

16-meter ultra-long seamless welding

Equipped with a high-precision ground track system, the welding operation radius covers 16 meters, making it easy to handle the overall welding of long- materials such as large H-shaped steel, bridge components, and pressure vessels, without the need for segmental butt welding. The ground track’s repeat positioning accuracy reaches ±.1mm, combined with a multi-axis linkage robotic arm, it can achieve continuous welding of complex welds, thoroughly solving the problem of cumulative errors in traditional manual welding joining long materials, and increasing material utilization by 8%-10%.

Multi-material compatibility and intelligent process adjustment

Supporting welding of various materials such as carbon steel, stainless steel, and aluminum alloys, it is equipped with an in-built welding database developed by Yawa. The system automatically matches the current, voltage, and travel speed according to the material thickness (0.5-50mm). For high-hardness alloy materials it employs pulse welding technology to reduce thermal input and prevent material deformation. The heat-affected zone is controlled within 0.3mm, ensuring that the material’s mechanical properties stable after welding.

Automation of processes for cost reduction and efficiency improvement

Integrated with automatic wire feeding and weld seam tracking (laser + visual dual sensing) functions, the entire process from material loading to welding completion does not require any manual intervention. The single-shift welding efficiency is more than three times higher than that of manual operation. The welding cycle for 16-meter-long materials is shortened by 50% compared to traditional segmented welding, and defects such as weld deviation and missed welding caused by manual operation are reduced, with the rework rate dropping to below 1%.

Quality stability lays the foundation for a high-end positioning.

The strength of the welding seams reaches over 85% of the base material. The weld seams are uniform and aesthetically pleasing, without defects such as pores and slag. They can meet the strict standards of high-end fields such as wind power and nuclear power. Compared to manual welding, the product consistency is improved by 40%, helping the enterprise obtain the qualification for high-end projects.

Overall welding of long materials expands application scenarios.

It can achieve integrated welding of structural components within 16 meters, breaking through the size limitations of traditional equipment, and giving the product a differentiated advantage in large-scale engineering tenders. For example, after the bridge steel structure is welded using this equipment, the installation accuracy is improved by 15%, the on-site construction period is shortened by 20%, significantly enhancing the willingness of customers to cooperate.

Cost optimization enhances price competitiveness.

Automation welding reduces the labor cost of 3-5 welders, the intelligent wire feeding system saves 15% of wire loss, and the implicit cost savings brought by the reduced rework rate, the overall manufacturing cost of the product is reduced by 20%-25%, giving the enterprise greater price maneuvering space in the competition of similar products.

The 16-meter ground rail welding robot focuses on the core values of “long material precise welding, efficient and stable, cost controllable”, which not only solves the technical problems of large material welding, but also helps the enterprise build a competitive barrier in the high-end manufacturing market through the dual advantages of quality and cost.

The 20-meter-long mobile laser composite welding machine features an extremely long operation radius and laser-electric arc composite welding technology as its core characteristics. It is specially designed for on-site welding of large-scale building components, perfectly meeting the splicing requirements of super-long-span structures such as bridges and venues. It provides efficient and high-quality welding solutions for the construction clients.

20-meter ultra-long movement, covering large-span scenarios

Equipped with a high-precision track movement system, the working radius can reach 20 meters. Combined with a telescopic mechanical arm (with a telescoping range of 0-3 meters), it can easily cover the full length welding of large steel components. The track’s repeated positioning accuracy is ±0.1mm. Even at the extreme distance of 20 meters, it can still ensure that the straightness error of the welding trajectory is ≤0.3mm/m, solving the problems of frequent shifting and insufficient alignment accuracy of traditional welding machines in welding of ultra-long components. It is particularly suitable for scenarios such as the main beam splicing of steel structure bridges and the welding of giant trusses in sports venues.

Laser – Arc Composite, Balancing Strength and Efficiency

Combining the high energy density of laser and the molten pool filling advantage of arc: The laser beam (with a power of 3000-6000W) is responsible for precisely melting the base material to form a deep weld seam, while the arc (with a current of 200-500A) simultaneously fills the welding wire, achieving the dual effects of “deep melting + reinforcement”. Compared to pure laser welding, the tolerable assembly gap of the component can reach 1-2mm (pure laser can only tolerate within 0.3mm); compared to traditional gas shielded welding, the welding speed is increased by 2-3 times, and the heat affected zone is reduced to within 0.5mm, significantly reducing the dimensional deviation of extremely long components caused by welding deformation.

Mobile design, adapted to the complex environment of the site

The equipment adopts a modular integrated design, with the main body weight controlled within 500kg. It is equipped with a crawler-type walking mechanism (climbing angle ≤ 15°), enabling flexible movement at the construction site. It is equipped with a windproof and dustproof cover (protection level IP54), and can still perform stable welding in outdoor environments with wind speed ≤ 8m/s, addressing the pain point of large construction sites with highly variable welding environments. At the same time, it supports remote control and real-time weld seam monitoring. Operators can monitor the welding process from 10 meters away through the display screen, enhancing operational safety.

›The value of the finished products for the construction client

›The super-long components welded by this equipment have a weld strength of over 95% of the base material, and the welding consistency error within a 20-meter length range is ≤ 1%. This ensures the integrity and load-bearing safety of large-scale buildings such as bridges and venues. Its efficient welding capability can shorten the on-site assembly cycle of large-span components by more than 40%. For example, the welding of a 30-meter-long steel box girder, which requires 3 days with traditional methods, can be completed by this equipment in just 1.5 days, significantly accelerating the project progress. Moreover, due to the small thermal deformation, the leveling work for the later installation of the components is reduced by 60%, indirectly lowering the construction cost. For exposed steel structures, the surface smoothness of the welds by laser composite welding reaches Ra6.3 level, which can reduce the grinding process by 80%, balancing structural safety and architectural aesthetics.

›The 20-meter-long mobile laser composite welding machine, with its core advantages of “super-long coverage, powerful combination, and on-site adaptability”, has become a breakthrough equipment for on-site welding of large-scale building structures, providing key support for the efficient construction and quality assurance of ultra-long-span projects.

The single-station welding robot is dedicated to high-precision welding operations at a single workstation. With its compact design and precise control technology, the fabricated building components demonstrate significant advantages in terms of quality and safety, providing reliable guarantees for the construction clients.

The weld quality is excellent, ensuring the safety of the building

The welded building components by this equipment have uniform and beautiful weld seams, without any defects such as pores or slag. The welding strength meets the standards and the stability is extremely high. Due to its repetitive positioning accuracy reaching ±0.05mm, combined with arc tracking and molten pool monitoring technologies, it can real-time correct the deviation of the welding trajectory, ensuring a more reliable connection strength of the components. This can effectively reduce safety hazards caused by welding issues in the long-term use of buildings, and meet the strict requirements of construction projects for structural stability.

The component dimensions are precise, which enhances the construction efficiency

For the fixed welds of building components such as flange connections and box body assembly, the equipment can achieve high-precision welding, thereby controlling the dimensional errors of the components within an extremely small range. This means that when the construction party assembles the components at the construction site, they can reduce the adjustments and repairs caused by dimensional deviations, accelerate the construction progress, shorten the overall project duration, and ensure the project is delivered on time.

Adapt to various demands and meet customized construction requirements

This equipment can weld various common materials such as carbon steel, stainless steel, and cast iron, and can quickly switch between different weld seam forms (such as fillet weld, vertical weld, flat weld, etc.). The finished components produced by this equipment can meet the diverse structural requirements in construction projects. Whether it is special-shaped decorative components or structural parts with high load-bearing requirements, they can precisely meet the needs and provide strong support for the customized construction of the building owner.

The finished products produced by single-station welding robots feature “high quality, high precision, and high adaptability”. They bring tangible benefits to the construction clients in terms of building safety, construction efficiency, and the satisfaction of customized requirements, thereby facilitating the smooth progress of construction projects.

The laser welding machine is characterized by its high-energy laser beam focused welding and non-contact processing. It demonstrates outstanding performance in connecting metal components, especially suitable for scenarios in the construction field where there are high requirements for welding accuracy, strength and appearance. It provides high-quality welding products for construction clients.

High-precision focusing, weld seam extremely fine

Using a 1064nm wavelength fiber laser, the beam is focused to a tiny spot size of 0.1-0.3mm through a precise optical system, with an energy density as high as 10⁶-10⁸W/cm². During welding, the heat affected zone (HAZ) can be controlled within 0.1-0.5mm, much smaller than that of traditional arc welding (2-5mm). This effectively avoids deformation and color changes in building components caused by welding heat. For thin-walled stainless steel decorative parts and aluminum alloy curtain wall frames, the weld seams are smooth and flat, and do not require subsequent grinding to meet the aesthetic requirements for exposed installation.

High-speed welding + intelligent tracking, efficiency doubled

The welding speed can reach 3-10 meters per minute, which is 3-5 times that of traditional argon arc welding. It also supports continuous welding and spot welding switching. Equipped with a laser visual weld seam tracking system (response time ≤ 0.1 seconds), it can automatically identify the position deviation of the weld seam and make real-time corrections. Even if the component has a slight deformation (≤ 0.5mm), the welding accuracy can still be guaranteed. For batch welding scenarios such as grid steel structures for buildings and metal roof joints, the single-shift production capacity can be increased by more than 40%.

Broadly compatible, capable of overcoming special materials

It can weld various commonly used metals in construction, such as carbon steel, stainless steel, aluminum alloy, and titanium alloy. It is particularly adept at solving welding problems for highly reflective materials (such as aluminum and aluminum alloys). By adjusting the parameters of the laser pulse, it can achieve various joint forms including butt joint, lap joint, and corner joint for plates with a thickness of 0.3 – 8mm, meeting different welding requirements ranging from precision decorative parts to load-bearing structural components. It can complete the processing of multi-material components without the need to replace equipment.

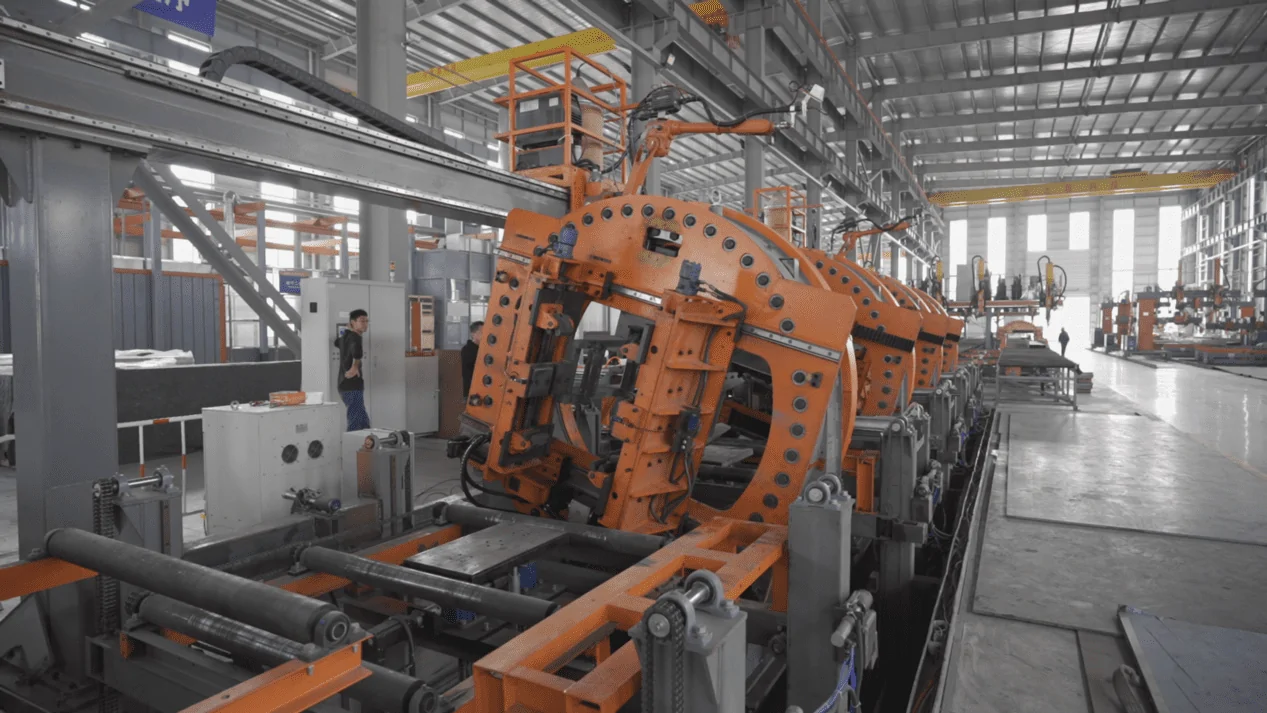

At the core performance level

The equipment adopts a fully intelligent unmanned feeding and conveying system combined with intelligent joint welding mode. The equipment’s floor space is significantly reduced compared to traditional solutions, saving valuable space in the production workshop. Through the self-developed circular rotating clamping function machine, the workpieces can be quickly assembled, eliminating the redundant time of the intermediate logistics transportation process. Through theoretical calculation and actual operation verification, the assembly and welding cycle (CT) is stably controlled within 10 minutes, and the assembly efficiency is significantly improved compared to traditional equipment. At the same time, the equipment has high flexibility and can flexibly adapt to the production of multiple specifications of workpieces, meeting diverse manufacturing requirements.

In terms of controlling labor costs

ASW realizes the entire process of single-site automatic feeding, conveying, assembly and spot welding. Only 0.5 workers are required to load materials onto the automated rail transportation shuttle vehicle. This significantly reduces manual intervention, reducing labor costs and avoiding human operational errors, ensuring production stability.

To address the industry pain point of H-shaped steel prone to uncontrollable deformation due to instantaneous high heat during submerged arc welding, the equipment is equipped with a laser tracking scanning welding system. It innovatively adopts a “scanning while welding” dynamic operation mode. By real-time tracking the weld seam trajectory and dynamically adjusting the welding parameters, it effectively suppresses workpiece deformation, while significantly improving the weld formation quality and appearance flatness, ensuring that the product accuracy and aesthetics reach the industry-leading level.

With its core advantages of “efficiency, intelligence, precision and flexibility”, ASW offers the most optimal solution for cost reduction and efficiency improvement in the welding production field, helping enterprises build a core technology barrier in the fierce market competition.

The automatic shot blasting and spraying production line is an efficient and convenient surface treatment equipment. At the product level, it also demonstrates many irreplaceable advantages.

This equipment operates in a fully automated mode. From the sandblasting process to the spraying process, no manual operation is required. Only one person is needed for monitoring, completely avoiding human errors and ensuring extremely high stability. In terms of quality, the roughness of the sandblasting can reach Sa2.5-Sa3 level, and the spraying thickness is precise to ±0.02mm. The product qualification rate remains above 99%, far exceeding the level of manual processing. The surface of the treated workpieces is smooth and uniform, with strong coating adhesion. It can effectively resist external factors such as corrosion and wear, significantly extending the product’s service life. Compared with traditional processing methods, the durability of the products has been improved by more than 30%.

The production capacity and cost advantages are remarkable. The single-shift production capacity is 3-5 times that of traditional equipment, and the production cycle is shortened by 40%. At the same time, a waste heat recovery system is equipped, which can reduce energy consumption by 25% and save a large amount of costs in the long term. The equipment is flexible and can adapt to multiple scenarios. It can handle workpieces ranging from 50 to 3000mm in size, suitable for various materials. It can be quickly reconfigured in 15 minutes and easily meet the production needs of small batches and multiple varieties. Whether it is small precision parts or large structural components, consistent and high-quality surface treatment effects can be achieved, ensuring the uniformity of product quality for different specifications and enhancing the market recognition of the products.

In the market competition, this production line has multiple advantages. The integrated design combines the functions of shot blasting and painting, reducing the movement of workpieces, saving space, and increasing the space utilization rate by 50%; the modular design reduces the initial investment by 30%, and additional workstations can be added as needed in the later stage for flexible expansion; moreover, the dust and paint mist recovery rate reaches 99.9%, fully complying with the new environmental protection regulations, ensuring that production is compliant and risk-free.

XTS-1530-24A stainless steel sand blasting machine is a highly efficient equipment specially designed for the surface treatment of stainless steel components in fields such as curtain wall construction. With its intelligent automation core technology and customized processing capabilities, it has become a key tool for enhancing project quality and reducing project costs. Its commercial advantages and market competitiveness are outstanding.

Core advantages of the equipment: Full-process automation, reducing costs while maintaining quality.

From the process of loading the workpiece to the completion of sandblasting, the entire operation is carried out without human intervention. Only one person is needed to monitor the system operation. This completely avoids the problems of uneven force and missed spraying in traditional manual sandblasting. The sandblasting accuracy can be precisely controlled within the preset roughness range. After processing, the surface of the stainless steel has no scratches or dead corners. The product qualification rate is stable at over 99.5%, far exceeding the average level of 80% achieved by manual processing. This directly reduces the waste of materials and construction period caused by rework.

For the design of large-sized stainless steel plates (with the maximum size of 1500×3000mm) in the curtain wall project, the single-shift production capacity is three times that of traditional equipment. The processing time for each plate is shortened to less than 2 minutes, easily meeting the centralized supply requirements of the project. The intelligent sand material circulation system can automatically adjust the sand quantity and spraying intensity, reducing sand loss by 30% and saving energy by 25%. The long-term operating cost advantage is significant.

Supports 24 preset sandblasting process parameters. It can complete the process transition from matte finish to mirror finish within 10 minutes. It is suitable for processing different types of stainless steel workpieces such as curtain wall decorative parts and load-bearing components. The modular structure design allows for expansion of sandblasting stations as needed in the later stage, reducing the initial investment cost by 20% and providing flexibility for both small and large projects.

Completely solve the problems such as “uneven surface precision affecting the appearance of the curtain wall”, “low manual efficiency slowing down the construction period”, and “difficult to meet dust pollution standards and facing environmental protection penalties”. The equipment is equipped with a 99.8% efficient dust collection system, which complies with the environmental protection requirements for the construction site of the curtain wall project, and eliminates the risk of work stoppage due to environmental protection issues.

The adhesion of the treated stainless steel surface has been enhanced by 40%, which can reduce the risk of detachment in subsequent spraying and installation processes, and lower the maintenance costs of the curtain wall in the later stage. The stable quality and efficient production capacity ensure the project is delivered on schedule, avoiding the loss of penalty fees due to delays. At the same time, it enhances the visual texture of the building facade and strengthens the market competitiveness of the project.

Our fully automated coating line is purpose-built to deliver high-performance surface finishes using the JOTUN 4-Coat System, consisting of epoxy primers, epoxy intermediates, and polyurethane (PU) topcoats. Designed for structural steel and façade components, the line integrates motorized conveyor systems, precision spray booths, and controlled curing ovens, ensuring seamless material flow and uniform application across all parts.

The system supports batch or continuous production modes, with automatic indexing, timed transitions, and environmental controls that optimize coating adhesion, layer thickness, and finish quality. Each workpiece undergoes a carefully sequenced treatment: abrasive surface preparation (Sa2.5), epoxy zinc-rich priming, high-build epoxy intermediate coats, and UV-resistant PU topcoat finishes, with total DFTs (dry film thickness) ranging from 180–300 microns depending on specification.

This coating line has been audited by third-party inspectors and is certified by JOTUN for compliance with AAMA 2605 standards, meeting stringent international benchmarks for corrosion resistance, weatherability, and film durability. With precise process control, heat-curing chambers, and in-line inspection stations, the system ensures maximum throughput, minimal rework, and consistent coating integrity for export-grade architectural and industrial applications.

The automatic cantilever mobile belt grinding machine adopts German technology and features a telescopic cantilever structure and an automated grinding control system. It is specifically designed for the surface treatment of large metal components, perfectly meeting the grinding needs of large structural components such as bridges and heavy equipment. It provides efficient and high-quality surface treatment solutions for construction clients.

The cantilever can move flexibly and cover a wide area for grinding

Equipped with a telescopic arm (with a telescoping range of 0-5 meters), combined with a 360° rotating joint, the working radius can be flexibly adjusted according to the size of the components, enabling it to easily cover the complex surfaces of large steel components, including curved surfaces, corners, grooves, and other difficult-to-manage areas. The arm’s movement accuracy reaches ±0.2mm. Even when handling super-long components over 20 meters in length, it can ensure the consistency of the grinding path, solving the problem that traditional sanding belt grinders cannot fully grind large components due to fixed position limitations. It is particularly suitable for surface treatment of components such as the beams of steel structure bridges and the bases of large equipment.

Automated grinding control, balancing efficiency and precision

Equipped with an intelligent numerical control system, it can preset various grinding parameters (sand belt speed 10-30 m/s, grinding pressure 5-30 N). It can automatically adjust according to the surface roughness requirements of the component. The sand belt is made of multi-layer composite material, combined with automatic tensioning and deviation correction functions, to ensure a stable and efficient grinding process. Compared with manual grinding, the efficiency is increased by 3-5 times, and the surface roughness can be precisely controlled within Ra1.6-Ra12.5, meeting the requirements for the smoothness of the component surface in different scenarios, and significantly reducing the problems of uneven surface quality caused by manual operation.

Mobile design, suitable for complex working environments

The main body of the equipment is installed on a crawler-type mobile chassis (with a load-bearing capacity of up to 5 tons), which can be flexibly moved on-site at the construction site or in the workshop. The climbing angle is ≤ 10°, and it can adapt to different working areas. It is equipped with dust-proof and noise-reduction devices, which can effectively reduce dust and noise pollution during the grinding process and meet environmental protection requirements. At the same time, it supports remote control and real-time monitoring. Operators can adjust the grinding parameters through the control console from a safe distance, improving the safety and convenience of the operation.

The value of the finished products for the construction client

After being processed by this equipment, large metal components have a smooth and uniform surface, effectively removing defects such as weld scars and oxide scales after welding, enhancing the corrosion resistance of the components and prolonging their service life. The efficient grinding capability can shorten the surface treatment cycle of large components by more than 50%. For example, processing a 10-meter-long steel box girder, traditional manual grinding takes 2 days, while this equipment can complete it in just 1 day, significantly accelerating the project progress. Moreover, the precise grinding accuracy can reduce the consumption of coating materials during subsequent painting, indirectly lowering the construction cost. For exposed steel structures, the surface after grinding can be directly subjected to decorative treatment, enhancing the overall aesthetic appeal of the building.

The automatic cantilever mobile abrasive belt grinding machine, with its core advantages of “flexible coverage, precise and efficient, and strong adaptability”, has become the ideal equipment for surface treatment of large metal components, providing strong support for the quality improvement and progress guarantee of large-scale construction projects.

The CNC bending machine, with its high-precision bending control and flexible process adaptability, performs exceptionally well in the processing of metal components. The finished products produced by this machine can bring various practical values to the construction clients, meeting the strict requirements of construction projects for metal components.

The CNC bending machine, with its high-precision bending control and flexible process adaptability, performs exceptionally well in the processing of metal components. The finished products produced by this machine can bring various practical values to the construction clients, meeting the strict requirements of construction projects for metal components.

The bending accuracy is extremely high, ensuring a perfect fit during installation

The metal components processed by the CNC bending machine can have a bending angle error controlled within ±0.5°, and the bending size accuracy reaches ±0.1mm. They can perfectly meet the size requirements of architectural design. Whether it is the steel used for frame construction or the special-shaped metal parts for decoration, they can achieve precise connection, reducing the adjustment procedures during on-site installation and improving construction efficiency, ensuring the stability and aesthetics of the building structure.

Adapt to various components and meet complex designs

The equipment can perform bending processing on metal sheets of different thicknesses (0.5 – 20mm) and materials (such as carbon steel, stainless steel, aluminum alloy, etc.). It supports various bending forms (right angles, arcs, multi-section bending, etc.). It can easily handle various complex component designs in construction projects, such as the irregular bending of curtain wall keels and the arc treatment of stair handrails, helping the construction client achieve unique architectural shapes and functional requirements.

The structure is stable and reliable, enhancing the safety of use

The CNC bending machine achieves precise pressure control and bending path planning, thereby preventing cracks and deformations in the metal components during the bending process, and ensuring the mechanical properties of the components. The processed metal components have indicators such as load-bearing capacity and impact resistance that meet the standards. They are unlikely to experience structural failure during long-term use in buildings, providing a strong guarantee for building safety.

The finished products processed by the CNC bending machine feature “high precision, wide adaptability and high reliability”. In terms of installation efficiency, design implementation and usage safety, they provide high-quality metal component solutions for the construction clients, promoting the high-quality completion of construction projects.

The CNC slotting machine, with its precise slotting processing capability and flexible process adjustment function, performs exceptionally well in the slotting processing of metal sheets. The finished products processed by it can bring multiple practical values to the construction clients, meeting the fine processing requirements of metal components for construction projects.

The slot has extremely high precision, ensuring the quality of the bending process

The metal plates processed by the CNC slotting machine have a slot width and depth error controlled within ±0.05mm, and the slot edges are smooth and flat. This provides a precise positioning foundation for the subsequent bending process, enabling the metal components to be bent with accurate angles and regular contours. It is particularly suitable for irregular-shaped components and precise frames in architectural decoration, ensuring that the components fit tightly during installation and enhancing the overall refinement of the building.

Adapt to various demands and meet complex structures

The equipment can perform slotting on metal sheets of various thicknesses (0.3 – 10mm) and materials (such as stainless steel, aluminum plates, copper plates, etc.). It supports various slot types including straight slots, inclined slots, and stepped slots. It can easily handle various complex structural designs in construction projects, such as the folded edge slotting of curtain wall decorative panels and the processing of joint slots for metal window and door frames. This helps the construction client realize diverse design concepts. The processing efficiency is stable, ensuring the project schedule.

The slotting process controlled by the CNC system is stable and efficient. The slotting cycle for a single sheet of material is shortened by more than 30% compared to traditional processing methods, and it can ensure the consistency of batch processing. This means that metal components meeting the requirements can be quickly provided for construction projects, avoiding the impact on construction progress due to delayed component processing and ensuring the timely advancement of the construction project.

The finished products processed by the CNC slotting machine have the significant characteristics of “high precision, wide adaptability, and high efficiency”. From the aspects of component quality, design realization, and project progress guarantee, they provide reliable processing solutions for the construction party, helping to ensure the high-quality implementation of the construction project.

Designed specifically for long tube processing, with a 12-meter ultra-long compatibility + 3000W laser power, it can easily handle batch production and directly address the traditional processing pain points.

All-in-One Cutting: Can cut carbon steel pipes, stainless steel pipes and alloy pipes with diameters ranging from φ30 to 500mm. The cutting speed for 10mm thick pipe materials exceeds 3 meters per minute. The cutting edges are smooth, with a verticality error of ±0.1mm/m, directly meeting the welding accuracy requirements.

Efficiency Doubled: Intelligent automatic feeding, 12-meter-long pipes can be processed fully automatically without human intervention. The single-cycle time is 50% shorter than that of traditional equipment. The single-shift production capacity is 300-500 pipes, making it easy to meet the schedule requirements without stress.

Cost Saving and Convenience: Intelligent material allocation saves 10%-15% of materials and eliminates the need for tooling. The imported core components are stable with few malfunctions. Ordinary workers can quickly master the operation. The labor and maintenance costs are significantly reduced.

Worried that the cutting of the long pipe is not smooth and affects welding? The verticality error of the equipment’s cut is ±0.1mm/m, directly meeting the welding accuracy, and no secondary processing is required.

Production capacity not meeting the tight schedule? The single-shift production capacity is 300-500 pieces. The cycle time for a single piece is 50% shorter than that of traditional equipment, ensuring the ability to expedite production. Severe material waste and high costs? Intelligent material allocation saves 10%-15% of materials, without tool wear, significantly reducing the costs of raw materials and consumables. Relying on professional skilled workers with high labor costs? Ordinary workers can get up to speed in a short period, imported components are stable with few faults, and labor and maintenance costs are greatly reduced.

We are proud to be at the forefront of intelligent steel fabrication and facade engineering in China, delivering reliable and sophisticated solutions for both domestic and international markets.

© 2025 JZM • Designed by SlideExpo