From robotic welding to CNC fabrication and Jotun-certified coating lines — JZM’s production capabilities combine craftsmanship with next-generation intelligent manufacturing.

30,000W laser cutting of exquisite steel products

For high-quality steel products, the requirements for cutting precision, edge smoothness and material adaptability are much higher than those for ordinary steel processing. The 30000W laser cutting machine precisely meets these core demands. In terms of cutting precision, the equipment is equipped with a dual-drive servo system and a dynamic focusing laser head, combined with a micrometer-level positioning sensor, which can control the cutting tolerance within ±0.05mm. Even for the complex patterns and small diameters (the smallest can be φ1mm circular holes) commonly found in high-quality steel products, it can achieve error-free shaping and perfectly present the design details.

Breakthrough in 30,000W Laser Cutting Technology

In terms of processing efficiency and material handling capacity, the ultra-high power of 30,000W enables it to easily surpass the cutting limits of traditional equipment: for high-strength and delicate steel with a thickness of up to 30mm (such as wear-resistant alloy steel plates), the cutting speed is increased by 80% compared to the 12,000W equipment. The cutting cycle for a single 1.5m×3m sheet is shortened to less than 10 minutes, significantly meeting the timeliness requirements for batch production of delicate steel products. At the same time, its unique beam mode can reduce the heat affected zone (HAZ) to below 0.1mm, avoiding deformation and performance degradation of delicate steel due to high temperature, ensuring that the mechanical properties and surface texture of the material are not damaged after cutting, especially suitable for high-end delicate steel components with strict requirements for flatness and toughness (such as precision mechanical enclosures, decorative metal curtain wall components).

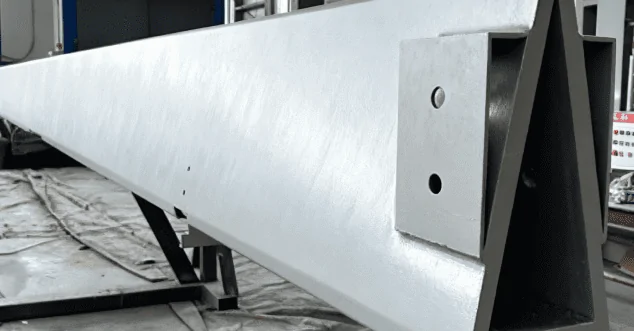

The bevel laser cutting machine is a high-precision equipment specifically designed for processing bevels of pipes and plates. With its 0-45° full-angle cutting capability and laser precise processing technology, it has become a key equipment in fields such as pipeline welding and steel structure connection. It can not only meet the diverse requirements for bevel processing, but also completely solve the efficiency and accuracy problems of traditional bevel processing.

Regarding the adaptability of processing for different materials, the equipment performs equally well. Whether it is stainless steel, carbon steel or high-strength alloy materials, the laser energy can be intelligently adjusted according to the material characteristics, ensuring that the thermal influence zone is reduced (controlled within 0.2mm) during the cutting of the bevel, avoiding material deformation or performance degradation due to high temperature. It is particularly suitable for high-end equipment manufacturing scenarios that require high precision. In addition, the equipment integrates an automatic loading and unloading system and a waste collection system, eliminating the need for manual intervention throughout the process. This not only reduces labor costs but also reduces safety hazards during the bevel processing (such as metal debris flying) by 40%.

For the common pain points of the client, such as “the cumbersome switching of multiple specifications of bevels” and “high costs for small batch customization”, the equipment achieves one-click switching of different angles and materials by presetting 100 + bevel process parameters. The changeover time is shortened to within 2 minutes, and the cost of small batch customization processing is reduced by 40%. At the same time, its integrated design eliminates the multi-device circulation process of “cutting + beveling” in traditional processing, increasing material utilization by 15% and further saving raw material costs for the client.

The bevel laser cutting machine has “full-angle precise cutting, efficient integrated processing, and multi-material compatibility” as its core competitiveness. It not only provides a one-stop solution for bevel processing, but also helps the client improve welding quality, shorten production cycles, and reduce overall costs. In the competition in fields such as pipeline engineering and heavy machinery, it has formed a significant advantage.For the common pain points of the client, such as “the cumbersome switching of multiple specifications of bevels” and “high costs for small batch customization”, the equipment achieves one-click switching of different angles and materials by presetting 100 + bevel process parameters. The changeover time is shortened to within 2 minutes, and the cost of small batch customization processing is reduced by 40%. At the same time, its integrated design eliminates the multi-device circulation process of “cutting + beveling” in traditional processing, increasing material utilization by 15% and further saving raw material costs for the client.

6000W Automatic Pipe Cutting Machine Solution

12-meter up and down 6000W automatic pipe cutting machine, with “ultra-long compatibility, efficient automation, and precise stability as its core competitiveness, not only solves the efficiency and precision bottlenecks of long pipe processing, but also helps the client to reduce labor costs, reduce material waste, and avoid project, providing a one-stop solution from raw materials to finished products for large pipe processing projects, and helping to take the initiative in the competition of project cycle and quality.

Breakthrough in 30,000W Laser Cutting Technology

In terms of processing efficiency and material handling capacity, the ultra-high power of 30,000W enables it to easily surpass the cutting limits of traditional equipment: for high-strength and delicate steel with a thickness of up to 30mm (such as wear-resistant alloy steel plates), the cutting speed is increased by 80% compared to the 12,000W equipment. The cutting cycle for a single 1.5m×3m sheet is shortened to less than 10 minutes, significantly meeting the timeliness requirements for batch production of delicate steel products. At the same time, its unique beam mode can reduce the heat affected zone (HAZ) to below 0.1mm, avoiding deformation and performance degradation of delicate steel due to high temperature, ensuring that the mechanical properties and surface texture of the material are not damaged after cutting, especially suitable for high-end delicate steel components with strict requirements for flatness and toughness (such as precision mechanical enclosures, decorative metal curtain wall components).

We are proud to be at the forefront of intelligent steel fabrication and facade engineering in China, delivering reliable and sophisticated solutions for both domestic and international markets.

© 2025 JZM • Designed by SlideExpo