Delivering world-class curtain wall systems, façades, and precision steel fabrication — powered by robotics, automation, and two decades of engineering expertise.

Project 1

JZM delivered high-precision steel curtain wall components for the landmark Beijing International Convention and Exhibition Center. The project required robotic hybrid welding, automated finishing, and full compliance with GB standards. Each component was manufactured to ensure architectural excellence, durability, and strict national standard compliance—showcasing JZM’s ability to handle large-scale, complex assemblies with both speed and precision.

Project 2

For this major façade project, JZM fabricated stainless steel panels under strict weld and surface requirements. Advanced flaw detection, precision sandblasting, and protective film coating ensured flawless quality and uniform finish across all batches. Every detail, from inspection certificates to surface treatment, was executed with uncompromising accuracy.

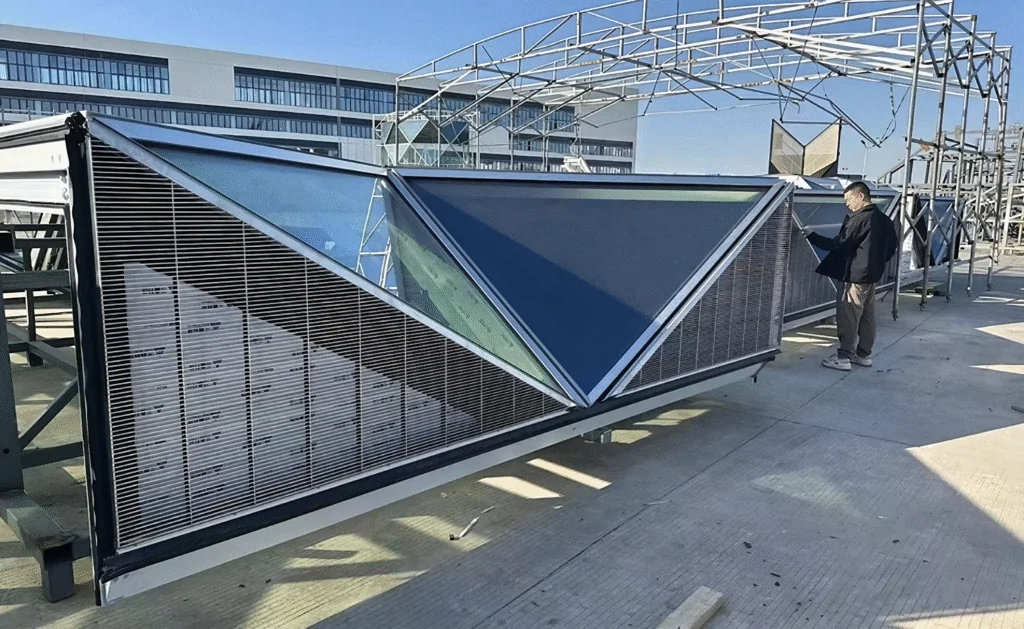

Project 3

JZM engineered and delivered stainless steel curtain wall louvers in 316L grade with bead-blasted finishes for consistency. Fabricated to ±1mm tolerance, these louvers achieved over 78% open-area ratio while meeting EN10088-1:2005 standards. The result was a high-strength, visually refined system for a premier financial institution.

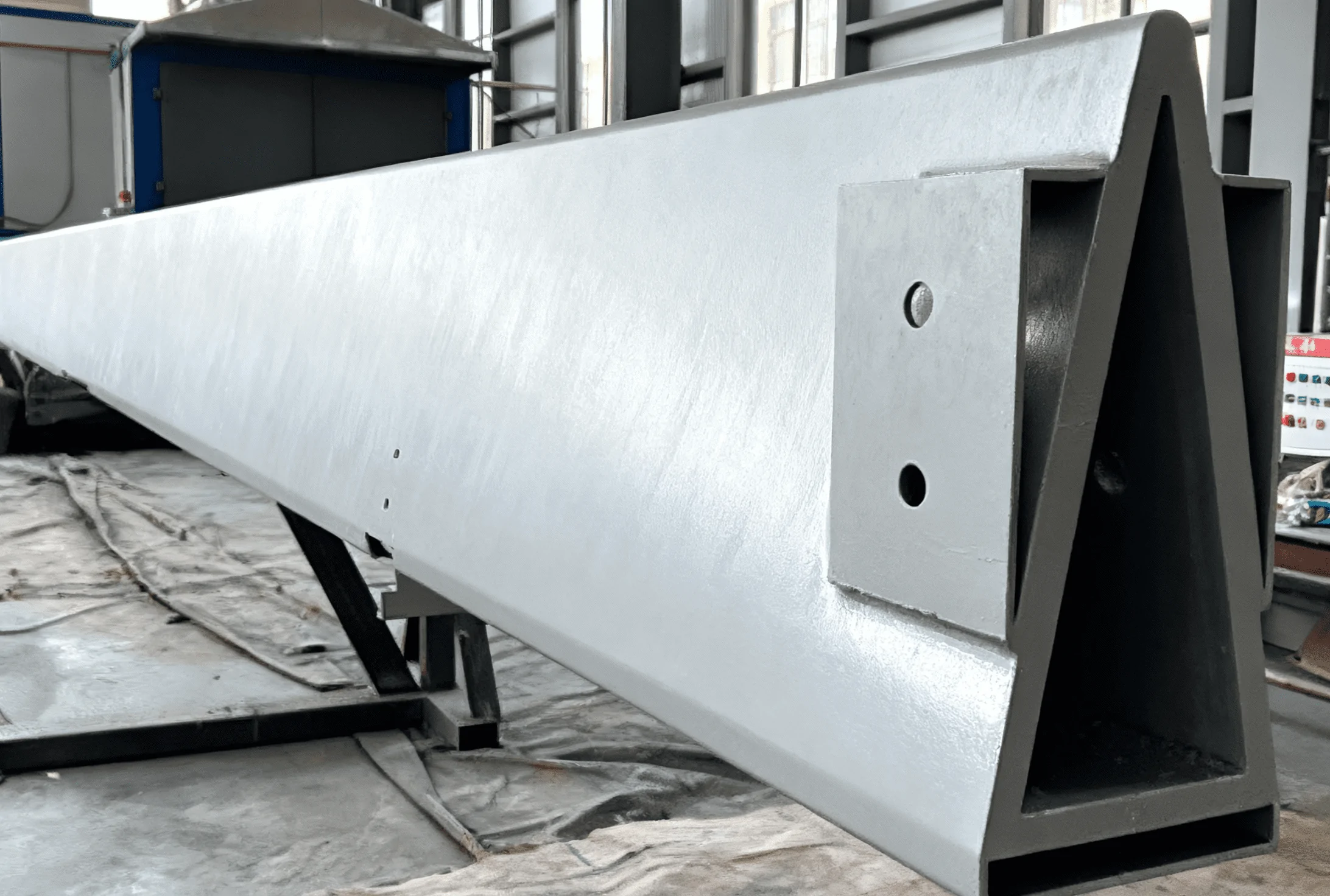

Project 4

JZM supplied Q235B steel curtain wall components with shot blasting, hot-dip galvanizing, and triple-layer fluorocarbon spraying. Designed to meet CB/13912-2020 and AAMA2605 standards, the system ensures 20+ years of durability under extreme conditions. Stringent welding and finishing practices guaranteed long-term performance and structural reliability.

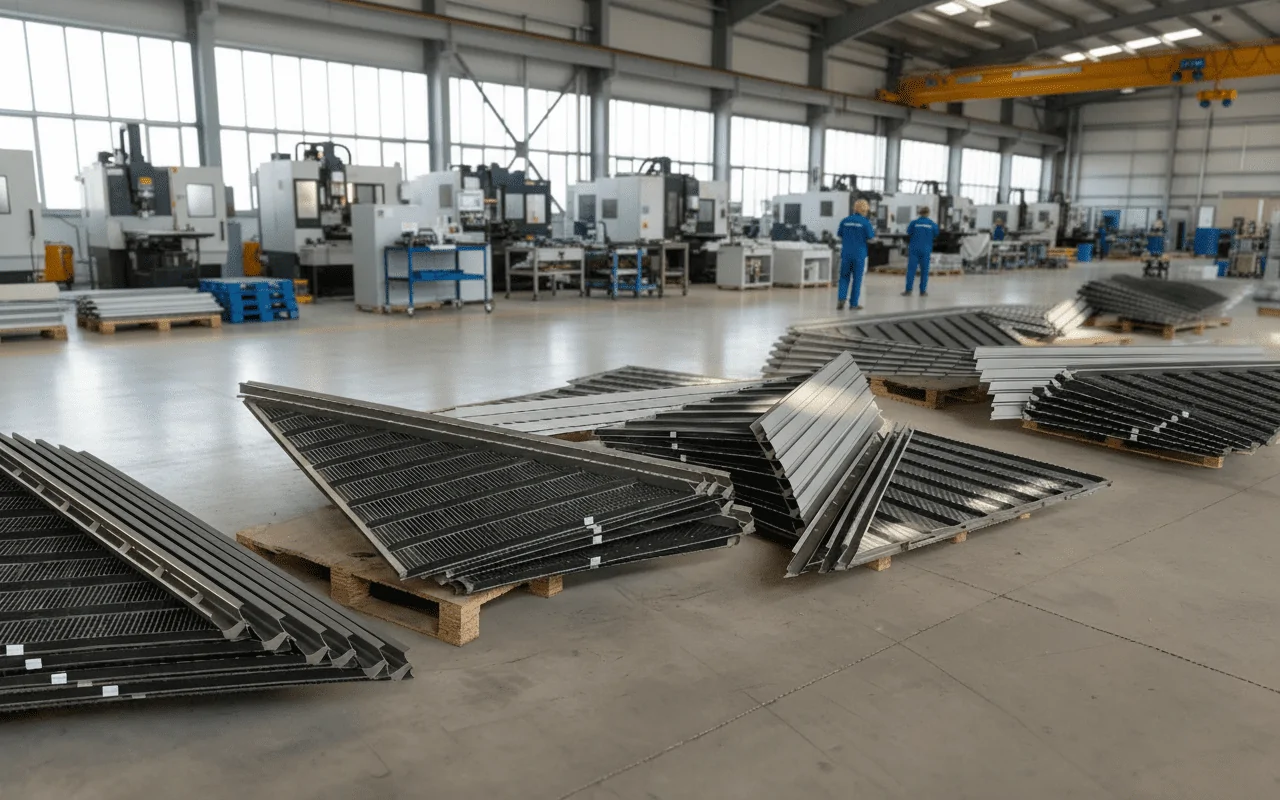

Project 5

JZM fabricated precision serrated steel brackets to ±1mm tolerances, with hot-dip galvanizing and fluorocarbon finishing for strength and durability. Welds were executed and inspected in line with BS EN and ISO standards, ensuring each unit met global benchmarks for safety and quality.

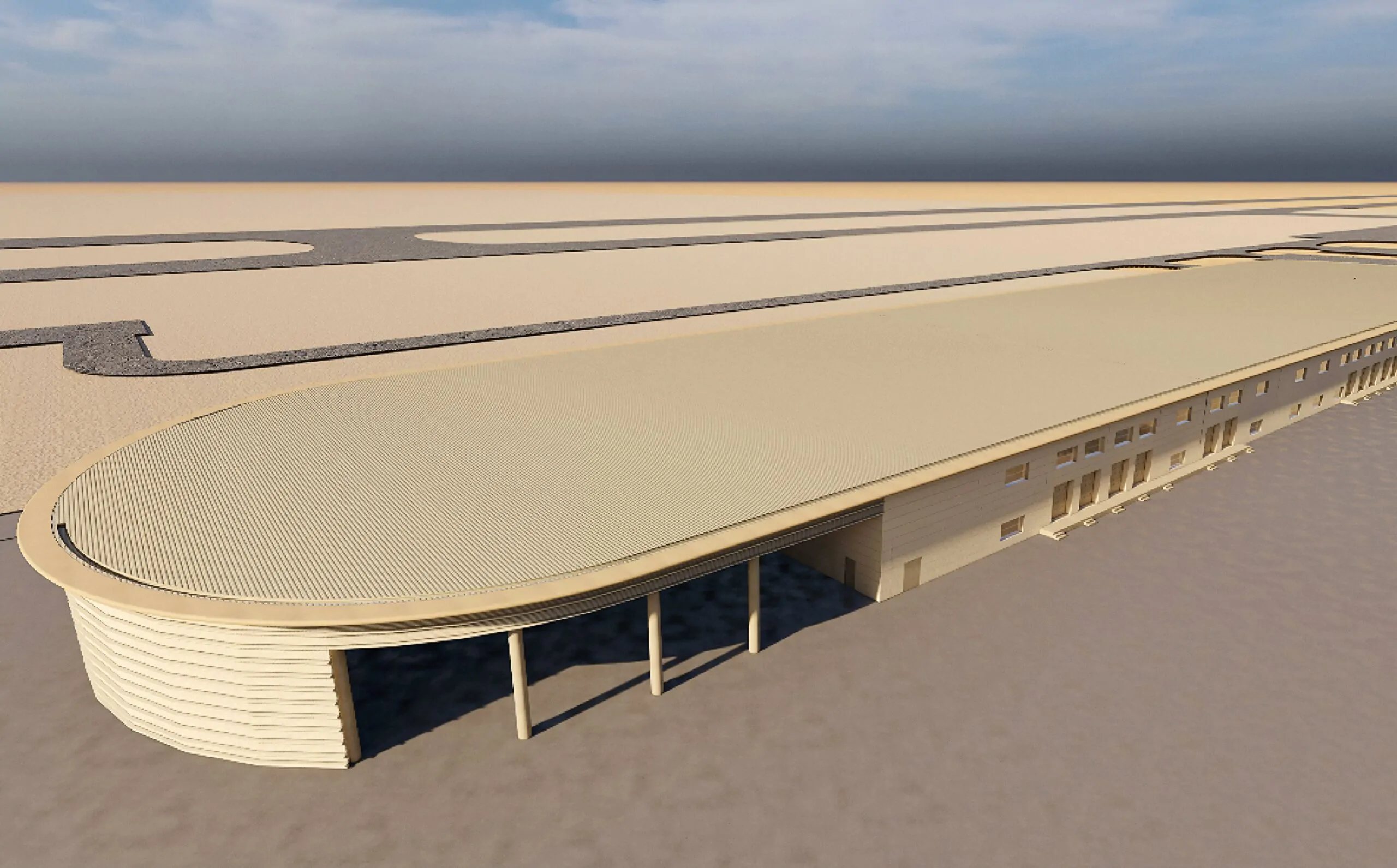

Project 6

JZM supplied S355JR hot-dip galvanized steel curtain wall components for Qatar’s main stadium. With ±0.25mm laser-cutting precision, chamfered details, and full-penetration welds, the assemblies were coated with Jotun’s three-coat system for long-term corrosion resistance. A showcase of engineering excellence for a global sporting event.

We are proud to be at the forefront of intelligent steel fabrication and facade engineering in China, delivering reliable and sophisticated solutions for both domestic and international markets.

© 2025 JZM • Designed by SlideExpo